Rockmate Blast OptimisationSoftware

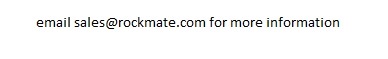

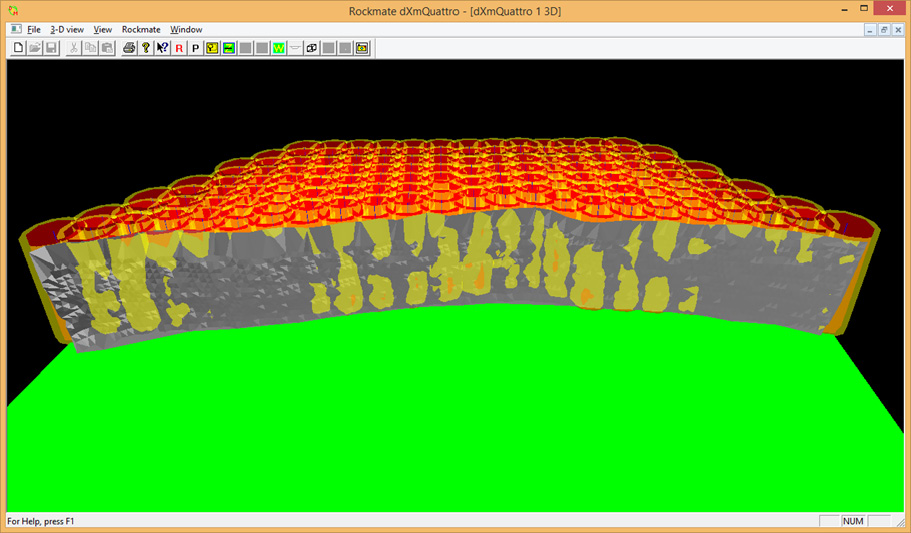

Rockmate uses data from non contact (reflectorless) survey instruments to model a blast, such as the Renishaws Plc's Quarryman and photogrammetry to model the rockface and the boretrak to add the blast hole positions to the model in order to reduce the risk of flyrock and improve the economics of blasting and mining. It is a blast design software tool designed to help the blasting engineer in his job.

Rockmate will reduce costs underground too. It will help reduce dilution in sub level caving methods and other underground mining methods. Please contact us for details.

Rockmate makes the connection between quality and costs. So many times

accountants look at the bottom line to the detriment of production managers -

cheap blasting = rubbish fragmentation. Rockmate will give consistent unit

blasting costs with consistent fragmentation blast after blast. The engineers

are happy because the fragmentation is consistent the accountant is happy

because his unit costs are the same blast after blast.

At least TEN reasons why you should purchase Rockmate

Rockmate BOS is employed in mines and quarries in Europe and China.

As with all Rockmate Limited's software, it is easy to use and help is never far away if it is needed. It uses all the tools available to support the blasting engineer, including 3D views, plans, and cross sections (profiles).

If you are having crusher production problems and not able to reach your tonnage targets and are seriously

considering introducing another crusher. It would be prudent looking at the Rockmate blasting system to achieve

those targets. Why not hire a rockmate engineer in for a month and measure the difference!

If you are having crusher production problems and not able to reach your tonnage targets and are seriously

considering introducing another crusher. It would be prudent looking at the Rockmate blasting system to achieve

those targets. Why not hire a rockmate engineer in for a month and measure the difference!

Rockmate Limited has the solution to easily measure the quality of your blast. Please contact us to find out how.

If you are in Open Pit Mining, vibrations can have a detremental effect on your slope

stability. Large tracked dozers should not travel around the rim of a pit unless on a low loader

because of the adverse effect that vibrations have on the stability of the slopes.

The effect of blasting operations on slope stabilty can be castastrophic. Rockmate

will help control the vibrations from blasting thus improving slope stability .

Cast Blasting: Spend a little more effort designing the blast with Rockmate and reduce the

quantity of rock to be excavated by your excavators!

In addition Rockmate can:

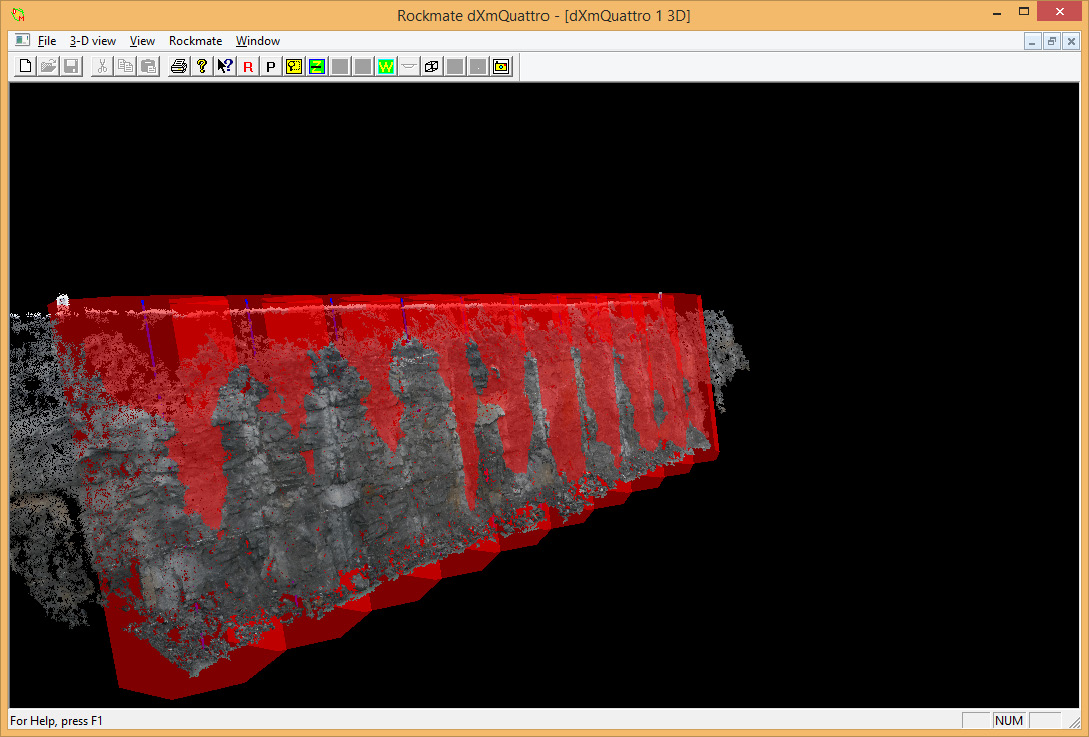

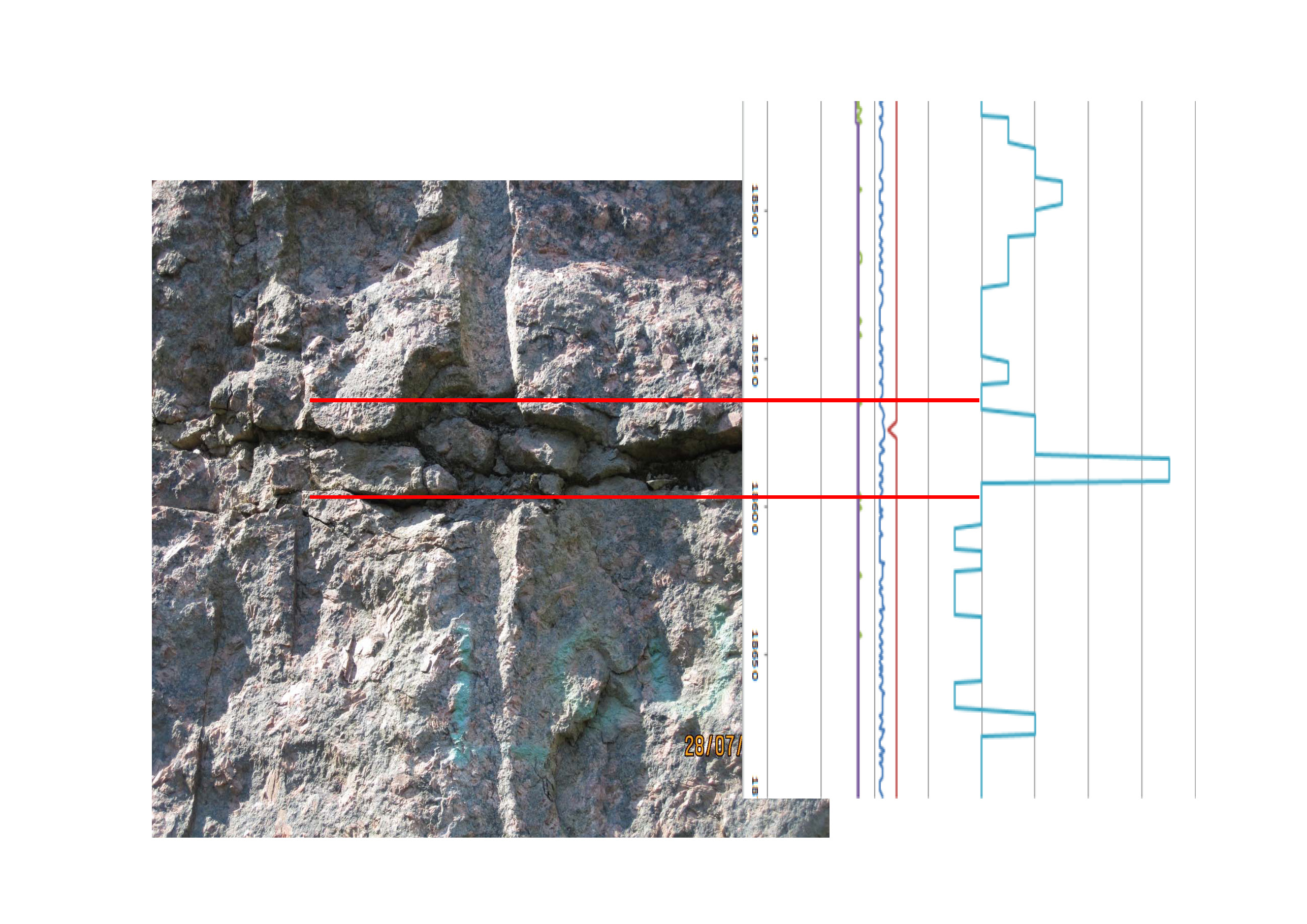

We have tools available to measure rate of penetration, for example to identify weakneness and hard bands in the rock. Contact us for more details.